Battery Testing Machine / Overcharge Explosion Proof Test Chamber 300mm*300mm*300mm

This 300mm³ Battery Overcharge Explosion Proof Test Chamber ensures safe, reliable safety testing with its robust protective structure.

MOQ: 1

Price: To be quoted

Standard Packaging: safety carton pack or plywood box

Delivery Period: 35 working days

Payment Method: T/T

Products Categories

Get A Free Quote

Product Description

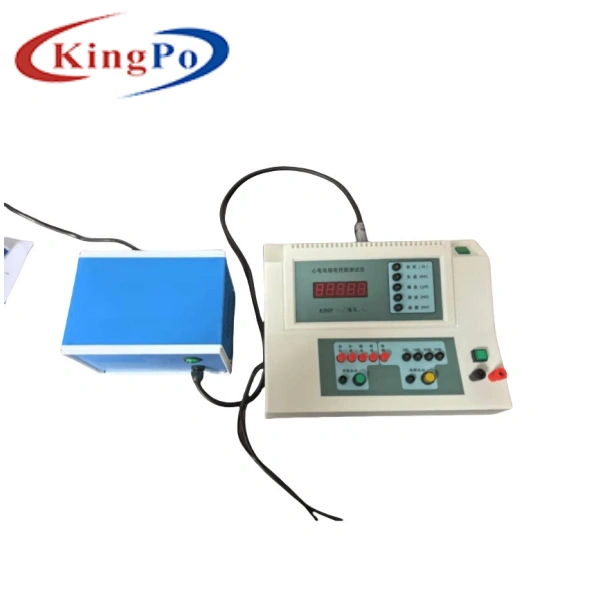

The battery overcharge explosion proof test chamber is used to test safety capability of battery through overcharging and over-discharging in the test chamber, check whether the battery will explode.

The battery will be placed in the explosion- proof chamber, the charging and discharging tester will be connected outside to protect operator and tester.

Detail Information

| Place of Origin | China | Brand Name | KingPo |

| Certification | iso9001 ce | Model Number | KP-FB-100 |

| Type: | Three Tanks | Weight: | 180kg |

| Internal Space: | 300mm*300mm*300mm | Corresponding Test Standard: | IEC 68-2-6(FC), GB2423, JJG189-97, GB/T13309-91 |

| Observing Window: | 5mm Tempered Glass | ||

| Highlight: | Battery Test Chamber, Battery Testing Equipment, Overcharge Explosion Proof Test Chamber | ||

Get Free Quote of Battery Testing Machine / Overcharge Explosion Proof Test Chamber 300mm*300mm*300mm

Technical Parameters

| Alternative name | Battery Overcharge Explosion Proof Test Chamber |

| Function | Place the battery on the test chamber, through over-charging and over- discharging, check whether the battery will explode |

| Type | Three tanks |

| Weight | 180kg |

| Internal space | 300mm*300mm*300mm |

| Corresponding test standard | IEC 68-2-6(FC), GB2423, JJG189-97, GB/T13309-91 |

Features

- The tester is used for testing overcharging and over-discharging of battery.

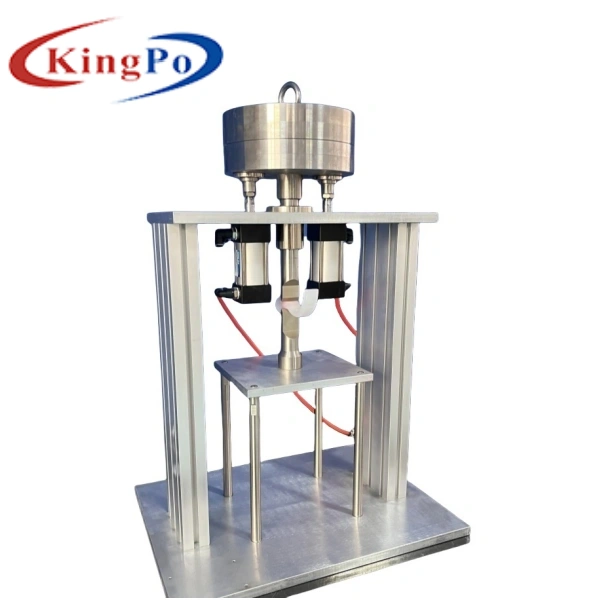

- The tester is divided three layer with three test chamber.

- Test result is non explosion, no fire, non air leaking, non electrolyte leakage for the qualified battery.

Specifications

| Model | KP-FB-100 |

| Dimension of each test chamber | 500*500*500mm (three layer) |

| Material | External box: A3 steel sheet with baking finish; internal box: SUS#304 |

| Door | Single door, double opening door made of stainless steel |

| Observing window | 5mm tempered glass |

| Accessories for door | Reinforce hinge; explosion proof handle locks |

| teflon sol cloth sticked 1/3 inside of internal box to anti-erosion | |

| Two round holes for connecting cables on the back with diameter φ50mm | |

| Separate air exhausting outlet for each test box | |

| Exhausting fan for each test box on the back with exhausting tube to connect reinforce exhaust fan outside laboratory | |

| Heat-insulation device for each layer to keep from inter- influencing |